Blog

November 19, 2018 in Uncategorized

Cut your losses

Sometime it is better to replace than to repair a boiler. Older systems can have a cascade of issues that spans over months or several seasons that can cost almost as the cost of whole system. Sometimes seeing the forest for the trees and cutting your losses before the suck you in a money black hole is the right decision. This replacement was the case. Older boiler was condemned due to combustion issues and a blocked heat exchager.

November 10, 2018 in Homeowner Tips, Our Work

Flame rollback

heat exchanger cleanout in a gas fired water heating boiler

November 9, 2018 in Our Work, Renovation

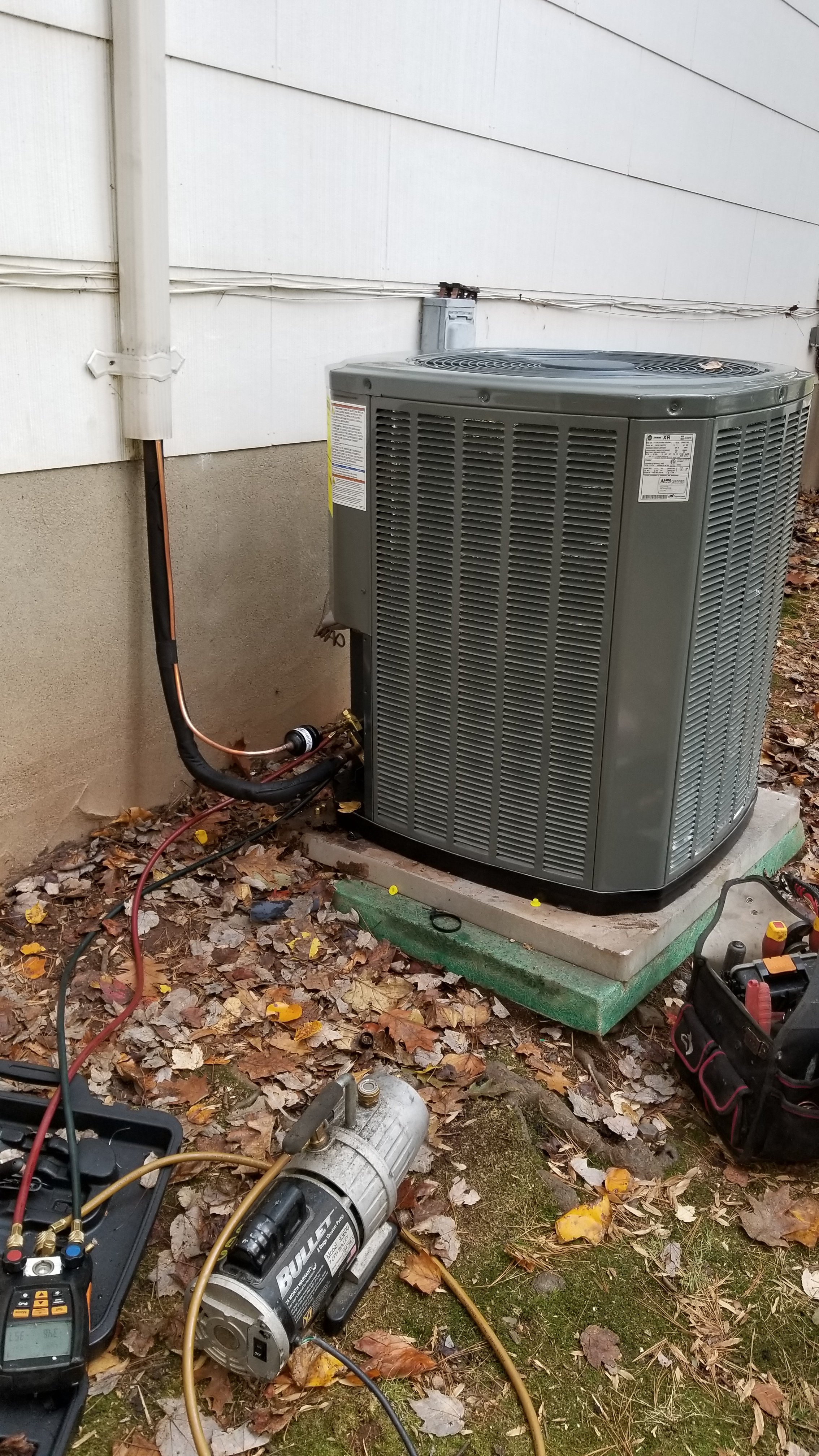

Central air changeout in the fall

Sometimes you know that the old system wont make it to next season. Doing a changeout in the “off” season allows for flexibility in all aspects of changing to new system. Also, milder attic temperatures allow technicians to not rush and work continuously without worrying about overheating.

October 26, 2018 in Our Work

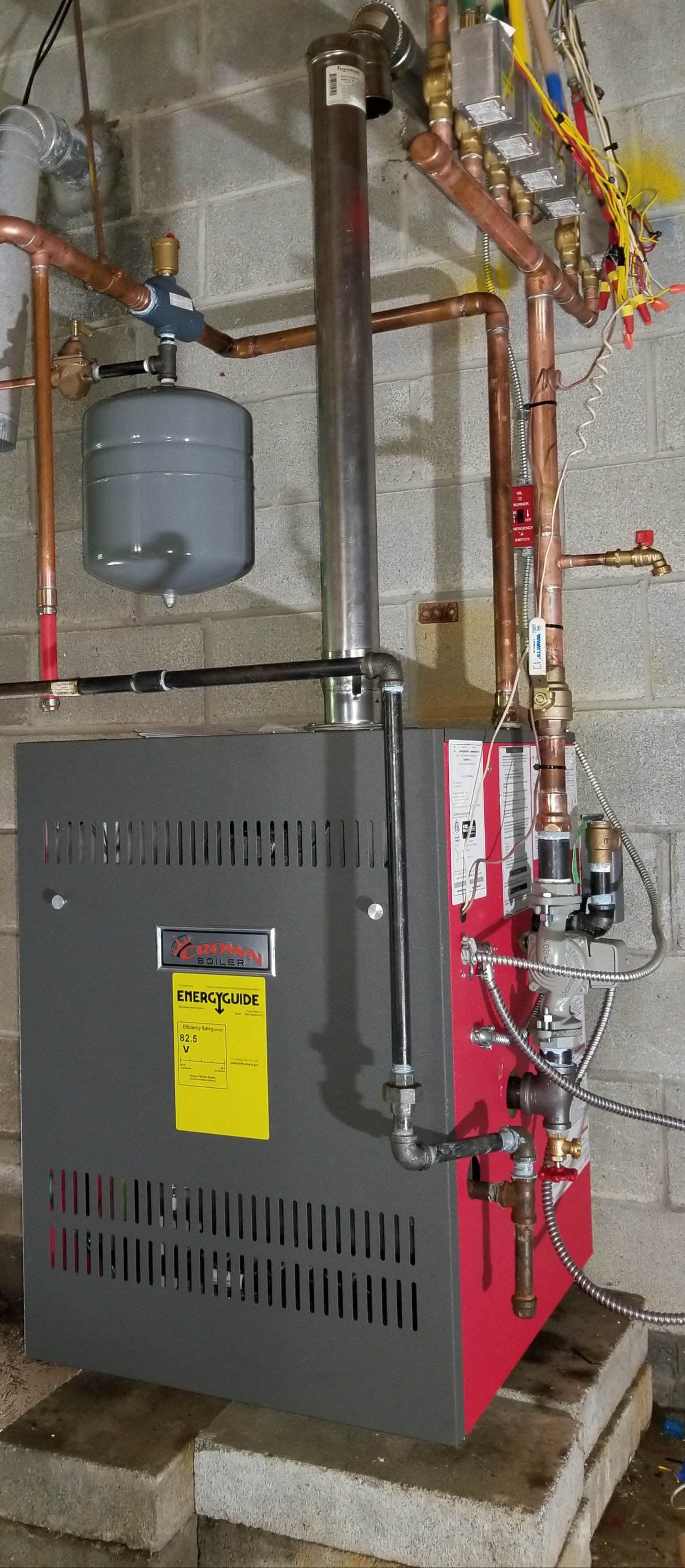

When you cant use the chimney

Sometimes a chimney is not usable.

In this situation we needed to install a new boiler and the chimney repair costs were too expensive. There is a solution for that situation.

It’s called forced draft boiler. It can be vented to side of house (with certain code restrictions). Crown was the biggest bang for the buck.

October 26, 2018 in Our Work

Pennco to the rescue

To replace a 40 year old dinosaur of a boiler we decided to go with Pennco boiler. Its a left side boiler (all accessories and controls are on its left side). When we install a boiler we look for best solution for customer and future serviceability.

October 24, 2018 in Our Work

Another one bites the dust

Before and after pictures of boiler replacement. Althougg the old one was working at time replacement, it was showing signs on being highly unreliable. Customer decided it was time to replace.

September 16, 2017 in Homeowner Tips, Our Work, Questions & Answers

Truth abough high efficiency tankless boilers

There are many good things to say about high efficiency/ tankless hot water heating boilers. You’ve heard many good things like the savings and the energy efficiency. These things are smart. Some units even come with an outdoor sensor that will adjust their output according to the temperature outside. So if it’s 20 out it will urn at 100%, but if it’s 60’s out it may modulate down to 30%. Smart! Modulation is another great feature. Ability to cycle down or up percentage of burning power. Like adjusting a burner on a range top. Standard counterparts only have 2 speeds and they are 100% or off.

Majority of high efficiency boilers are condensing. Which means that they are able to utilize/absorb more heat from combustion than their standard counterparts. Flue/combustion gasses leaving these boilers are much less hot than that of standard counterparts (650°F vs 80°F). Since these gasses transfer/lose/utilize so much heat @ combustion, condensation occurs.

Now lets delve into potential weaknesses. First and most obvious, these systems are much more complex than their standard counterparts and have a lot more parts functioning. Statistically speaking the more parts the more chances there are for malfunction of one of these parts. What should also be considered is our water. We have very hard water. It mineralizes everything, especially boiler insides. This buildup sometimes hinders the function of all of these sensors and malfunction may occur. Manufacturers recommend a chemical wash every year. This process removes all mineral buildup and cleans the insides of the boiler, however this is a time consuming task that is also significantly more expensive than a standard boiler maintenance. On a side note a water softener significantly reduces this buildup accumulation. Condensation can be an issue if exhaust is not properly installed. Shall other general malfunction to occur not all techs are able to diagnose the issue. Parts are typically very brand and model specific, which leads parts (un)availability.

High efficiency boilers are the pinnacle of HVAC technology. However, for a homeowner it is a costly investment, which also requires annual upkeep.

high efficiency Quietside combi boiler installation

Triangle Prestige High efficiency boiler